Cement Manufacturing Process | Phases | Flow Chart ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

WhatsApp)

WhatsApp)

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Cement Mill Grinding Balls, Wholesale Various High Quality Cement Mill Grinding Balls Products from Global Cement Mill Grinding Balls Suppliers and Cement Mill ...

Welcome to AIA Engineering/Vega Industries. Specialist in Cement, Mining, Power and Aggregate Businesses

Savona Equipment offers new and used Ball mills for sale ... lines for powders such as cement ... suitable for use in a ball mill, including ceramic balls, ...

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

Zhejiang Mayang Industries Co.,Ltd. the reviser of GB/T Standard of Manganese Steel Casting. (Original Wuyi Mayang Precision Casting Factory) is a ...

different types of grinding mills and basis of selection Grinding in Ball Mills: Modeling and Process Control – Cybernetics ... for different cement qualities ...

Used Cement Ball Mill, Wholesale Various High Quality Used Cement Ball Mill Products from Global Used Cement Ball Mill Suppliers and Used Cement Ball Mill .

FORGED STEEL BALLS — LARGE DIAMETER Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is the two ...

Available in 50Lb bags, the Loucast 3000 castable refractory is designed to withstand high Sulphur fuel, erosion abrasion. Buy today from Sheffield Pottery!

Cement Ball MillJiangsu Zhongbo Machinery the classifiion of the ball mill for cement,and ball mill for cement working principle. Raymond Mill Speed Influence ...

Bolted shell liners, tube mill internals, boltless shell liners for cement mills from AIA Engineering Ltd.

Nelson Machinery Equipment Ltd. Liquidations, Consignments, Appraisals since 1992

raw mill balls which material used. raw mill building in cement industry. to 53~55tph raw material ball mill in cement production line the 4 rong adapability Cement ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

How is cement manufactured? Learn cement manufacturing process thoroughly.

Aug 12, 2009· Video embedded· A narrated description of the steelmaking process.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

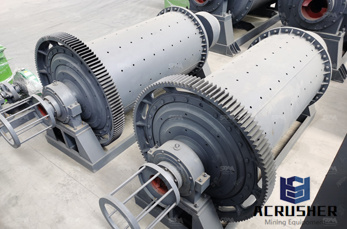

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

WhatsApp)

WhatsApp)